Steve Gainey holds his new creation, the "X Factor."

To find out what’s currently ailing the economy of the United States of America, look no farther than Gainey Ceramics’ struggle to survive. The proud 62-year-old manufacturing company of exquisite tiles, planters and other hand-crafted clay marvels is a company at the crossroads. More accurately, it’s a company in the crosshairs of regulators and economic policy makers gone amuck.

Just a couple of years ago, the La Verne, Calif., company sitting on six acres on the eastern edge of the San Gabriel Valley employed 180 talented workers. Today that number has dwindled to 15. The company has the capacity to process 25 tons of material a day; it currently produces two tons a day. In the 1980s, it was one of the hundreds of members of the American Ceramics Society of Southern California. Today, that society is extinct.

What Gainey Ceramics has going for it is its dynamic and passionate leader, Steve Gainey, a third-generation owner, who grew up in the business that his grandfather, John, Sr., and father, John, Jr., founded in 1949. The company started out making crockery and pet feeders, and, shortly thereafter, ceramic “ollas” – rotundly handsome earthen jugs used to cool water through condensation. In the Southern California of the 1950s and ‘60s, it was hard to find a kitchen or sun porch without one.

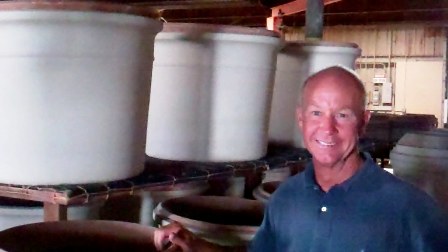

John Gainey, pictured in front of the company's trademark ollas, founded the company in 1949, when Southern California was a hot hub of ceramics manufacturers.

Today, what keeps the lights turned on, while Gainey brings new products to market, are its decorative classic and contemporary planters – immense, shapely vessels that are very much a part of the interiorscape of malls, hotels, government buildings, cruise ships and bank lobbies. Boutique versions also fit perfectly on table tops, stairs or the floors of well-appointed homes, providing just the right accent of color and style for their discriminating home owners. Among its most ardent admirers, Gainey products were more coveted than Bauer Pottery and other ceramic collectibles in post-World War II Southern California.

Now 56, Gainey, more than ever, is a man on a mission. His love of bringing beautiful ceramic products to market is what drives this clay crusader from his waterfront Balboa Island home to La Verne five days a week. A lifelong longboarder, he doesn’t have to surf the freeways anymore. He has ridden enough waves of success to comfortably live out the rest of his life, but he can’t quite get the clay and the talc out of his system. He wants to win. He wants America to win, again.

“We’re a great story,” said Gainey, whose bright smile and crisp handshake mirror the colorful glazes on his company’s trademark pots and planters.

But the story is changing monthly, even daily, buffeted by a depressed real estate market, tight-fisted lenders and ivory tower regulators who seem more bent on driving once-thriving businesses off shore than bending over backwards to encourage them to stay when America needs jobs, jobs, jobs.

“With the decline in the housing industry and with banks being unable to loan money, people don’t have the $50,000 to remodel their kitchen anymore,” Gainey said, inside his office. “They would buy a new range, a new refrigerator, and new cabinets and put in new backsplashes and countertops. They’re not doing that anymore.”

Gainey's Florentine tile was produced at the La Verne plant.

In response, Gainey decided this summer to discontinue tile production, the company’s own as well as private label lines for such prestigious companies such as Walker Zanger. It was a Pareto Principle-type decision, where the fiscal books showed that 80% of the company’s resources were producing only 20% of the company’s profits.

To his chagrin, Gainey has discovered that to take his tile-making machines off-line requires reams of red tape and, worse, thousands of dollars. If he lets the permits on the machines expire and then later decides to restart production when the economy improves, he would have to endure the entire expensive re-permitting process. “It’s not easy to get a piece of equipment permitted,” Gainey said. The alternative, to pay for permits for unused equipment, makes even less sense.

So for starters, Gainey has embarked on a letter-writing campaign to the 15 members of the Air Quality Management District. He’s heard back from two, saying, in effect, they’d look into the matter. “I’m simply asking to create some rules that allow me to mothball some of my equipment without incurring a huge expense to do so,” Gainey explained. “I’m hoping they can come up with some kind of mechanism.”

It’s not that Gainey doesn’t like to follow the rules. Indeed, he and his company are strong proponents of “green” regulations that protect the environment.

Gainey’s ceramic products are produced 100% at its La Verne factory. All of its clay bodies contain in excess of 25% recycled materials. Moreover, 100% of the water used in the production process is recycled back into the clay. “We capture and recycle all of the waste water from the production process,” Gainey said.

Any time it rains, Gainey collects samples of the run-off and sends it to a certified lab to be tested. Remarkably, the state doesn’t require the same stringent oversight of its streets and highways whose accumulation of asbestos from brake pads, motor and transmission oils and rubber flow unchecked into the region’s streams, lakes and oceans whenever it rains.

Nor does Gainey Ceramics during any of its spraying operations vent to outside air. Glaze overspray is trapped in fabric filters and recycled. Meanwhile, its energy-efficient kilns are BACT- (Best Available Control Technology) certified, the current highest standard available.

Gainey Ceramics has always been a colorful place to work.

When Gainey isn’t preoccupied writing letters to the AQMD, EPA, OSHA, CARB, Weights and Measures, the Census Bureau and dozens of other regulatory and bureaucratic agencies, he actually likes to produce things – beautiful things.

“Maybe over the last year, I’ve spent about half of each day out back,” Gainey said. As business conditions have changed, he’s started tapping into the right side of his brain again, creating ceramic bird feeders, vases, hanging circle pots, mixing bowls, a ceramic barbecue and other whimsical, yet practical products intended for the retail market, unlike the commercial clients that have long been Gainey’s bread and butter.

“It’s something I’m good at,” Gainey said. “You adapt and then you say, ‘Wow, maybe I should have been doing this all along.’”

Gainey has also been rummaging through old notebooks and catalogs dating back a half century or more filled with precious designs and drawings of past products he would like to revive as part of a new “Gainey vintage” line. He is re-testing 50-year-old formulas, including one for a stoneware glaze.

“I’ve been digging through piles of stuff trying to find the old molds,” Gainey said, relishing his new role as factory archivist and archeologist. “I’ve been working on the modern stuff, but why not go back in history and reintroduce some of our best stuff from an earlier era. We have really cool history that most companies don’t have.

“We have a rich tradition and legacy,” Gainey added. “That’s why we think recreating some of this stuff could be potentially important. We’ve reopened the vault, and what we’ve found inside is classic. Today, you see some of it on eBay sold for outrageous amounts of money. There are Gainey collectors out there.”

Gainey produces vessels and planters of all sizes.

Gainey can make a strong case for reviving its past strictly because it’s a big part of its legacy and tradition. Unlike some companies that buy patents or trademarks or pay royalties and go into business reproducing another company’s wares, Gainey would simply be reinventing itself.

“That’s sort of where we’re headed,” Gainey said. “We’re reintroducing original Gainey.”

Another part of Gainey’s strategy is to partner and collaborate with talented artists from around the country. Sometimes, Gainey finds the artists and sometimes they find Gainey.

“We’re talking to ceramic artists around the country who don’t have the capability of manufacturing in quantity,” Gainey said. “We can do things on a grand scale. We have capabilities that very few companies in this country have.

“We can help artists take their creations out to the world. That’s very liberating and inspiring to us.”

Gainey’s remaining staff may be relatively small, but it is immensely talented. The typical Gainey worker averages about 20 years with the company, each cross-trained to fulfill many different functions and processes. There are clay processors, and jiggermen to throw and shape the clay, and kiln operators, sprayers and finishers, to name a few of Gainey’s key personnel.

“Everybody’s doing everything,” said Gainey, who is probably the best example of his company’s versatility. “There are no egos here.”

The Profit Pit: Steve Gainey stands in front of a glacier of broken pots ready to be recaptured in the plant's ongoing recycling process

Gainey Ceramics can take a product from concept to completion in about two weeks, a period that comprises designing and drawing, creating molds and then the actual production process of making the clay, forming the object, finishing it and firing it, then glazing and firing it again. “It’s not like baking a cookie,” Gainey said.

Gainey is very much the ultimate (not ultra) conservative – not in a Republican or Democratic sense, but as a steward of American resources and the nation’s rich legacy based on the belief that “even with less you can still do your best.”

“We can’t lose 100% of our manufacturing base in America,” Gainey said. “Somebody’s got to say, ‘We’re staying.’

“At Gainey, we’re going to try to do everything we can to stay. We’re going to try everything we can to be as clean as possible, to be as efficient as possible.”

Gainey has conceded production of its fiberglass and fiber clay products to China and Mexico “because it simply wouldn’t be worth the expense of trying to get the permitting here to use the resins and the VOCs (volatile organic compounds) we would need,” Gainey said.

And it would be easy to surrender the remainder of the business as well. “There are thousands of companies over there that would love to do produce our ceramic stuff,” he said.

But Gainey doesn’t want to run up the white flag. He’d rather draw a line in the clay dust and fight. He sees his company’s turf as ground zero for a fight that he believes has to take place all across the country among small manufacturers. Admittedly, he knows it’s an uphill battle against nations who pay their workers low wages while Americans have gotten used to accepting more entitlements and less responsibility.

Yet Gainey remains optimistic. He still believes the world’s competitors are no match for American ingenuity and creativity. Top-tier companies like Tiffany have seen their company stock soar this year because its brand and reputation for quality defy replication. Gainey wants to cast his ceramics company in that mold and build on the legacy of craftsmanship that his father and grandfather instilled in him. Gainey bought the company from his father in 1986.

Gainey created this bird feed, which can be purchased at Gainey's new retail store.

“We just have to be creative and stay one step ahead of our global competition because they’ll copy you as soon as you create something cool that catches on,” Gainey said. “They’ll see it and flood the market with it. That’s when you have to move on to something else. You just try to stay ahead of them. You have to create things that are unique and different and that people feel good about owning.

“I think being a unique company like us has some appeal,” Gainey added. “There are so few of us left. There has to be a resurgence.”

Gainey may be at a crossroads and in the crosshairs of a huge global economic reordering, but Gainey isn’t backing away from the challenge. He’s got a few cards to play, including his company’s low debt and more than 60-year reputation for producing quality, innovation and value.

“We have seen many manufacturers disappear from our shores, but we are very proud to still be here and employing our neighbors in the manufacturing of high-quality products,” Gainey said. “And we look forward to training the next generation of skilled craftspeople here at Gainey.

“We’re not asking for special help from anyone,” he concluded. “But we’d also ask for a little less interference as well, so that we can create an environment that’s a win/win for our company, our workers and our partners. ”

Gainey Ceramics has just launched a retail store, with store hours from 10 a.m. to 5 p.m., Monday through Saturday. You’ll find the shop a great place for unique gifts to suit any season or occasion. Gainey Ceramics is located at 1200 Arrow Hwy. For more information, please call (909) 593-3533 or visit www.gaineyceramics.com.

Gainey Ceramics has just launched a retail store, with store hours from 10 a.m. to 5 p.m., Monday through Saturday. You’ll find the shop a great place for unique gifts to suit any season or occasion. Gainey Ceramics is located at 1200 Arrow Hwy. For more information, please call (909) 593-3533 or visit www.gaineyceramics.com.

Leave a Reply